Prefabricated eco-house, fast assembly

Steel pipes, Laser machinery, UAV

Water/gas treatment, Cooling water

Prefabricated eco-house, fast assembly

Steel pipes, Laser machinery, UAV

Water/gas treatment, Cooling water

装置.jpg)

The company's catalytic combustion (CO) device for the purification of organic gases (VOCs) is better than the adsorption purification device.

The device makes use of the characteristics of organic gas (VOCs) such as flammability and high heat release, and the process is advanced and reliable. The device consists of preheating system, heating system, catalytic system and automatic control system. The device has the advantages of skid mounting, small floor area, convenient transportation and installation.

Catalytic combustion is the complete oxidation of combustibles by means of catalysts at low temperatures (200-400 C). The essence of catalytic combustion is the deep oxidation with active oxygen. With the help of catalyst, the organic waste gas can be burned flamelessly at lower ignition temperature, and oxidized into CO2 and H2O. At the same time, a large amount of heat energy can be released to remove harmful substances in the waste gas.

In the process of catalytic combustion, the role of catalysts is to reduce the activation energy, while the catalyst surface has adsorption effect, so that the reactant molecules are enriched on the surface, which improves the reaction rate and speeds up the reaction.

Technological process:

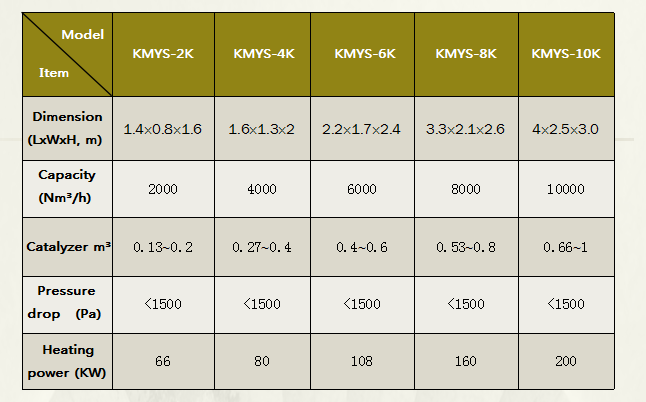

KMCO series parameters:

Remarks:

1. The performance parameters of some equipments are listed in the table, which can be designed and manufactured according to the actual working conditions;

2. Catalysts are well-known brands at home and abroad;

3. The heater adopts explosion-proof design.

Device features:

1) It is suitable for the treatment of organic gases (VOCs) with air volume less than 20000m3/h and concentration less than 2x10g/m3;

2) High safety performance, explosion-proof grade and protection grade meet the relevant requirements;

3) Long service life of catalyst;

4) Low resistance, saving operation cost;

5) The waste heat after combustion can be reused;

6) The purification efficiency can reach over 98%;

7) Integral prying design, easy to install;

8) Low energy consumption in operation, energy saving and consumption saving.

Application area:

It can be used in insulating materials, enameled wires, coating, printing, rubber synthesis, rubber products, electronic semiconductors and other industries.

Copyright All Rights Reserved @Shanghai Chemmah Industrial Co., Ltd.

Address: No. 528, North Yanggao Road, Pudong District, 200137, Shanghai, China

Email: sales@chemmah.com

WhatsApp & Messenger: +86 158 6847 7948