Prefabricated eco-house, fast assembly

Steel pipes, Laser machinery, UAV

Water/gas treatment, Cooling water

Prefabricated eco-house, fast assembly

Steel pipes, Laser machinery, UAV

Water/gas treatment, Cooling water

装置.jpg)

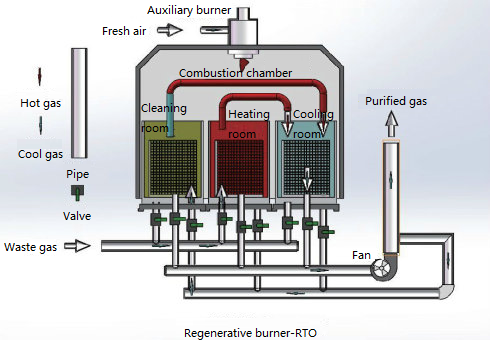

Our environmental regenerative combustion (RTO) device is a highly efficient purifying device which can completely destroy organic gases (VOCs) and meet the requirements of clean emission.

The device consists of reaction system, regenerative system, auxiliary combustion system and automatic control system. The company has designed and developed various types of regenerative combustion (RTO) devices, which are divided into single chamber, two chambers and three chambers RTO devices to meet the processing requirements of different working conditions.

Technical Principles:

Organic exhaust gas is introduced into the combustion chamber and burns at about 800 C, generating clean emission of CO2 and steam. The heat generated after combustion is absorbed by the regenerative material according to its endothermic-exothermic characteristics. When the next combustion process is carried out, the regenerative material contacts with the exhaust gas and releases heat. The heat absorbed by the exhaust gas reaches the ignition point of combustion, and the heat generated by combustion is absorbed by the regenerative material, and the whole process is circulated.

Technological process:

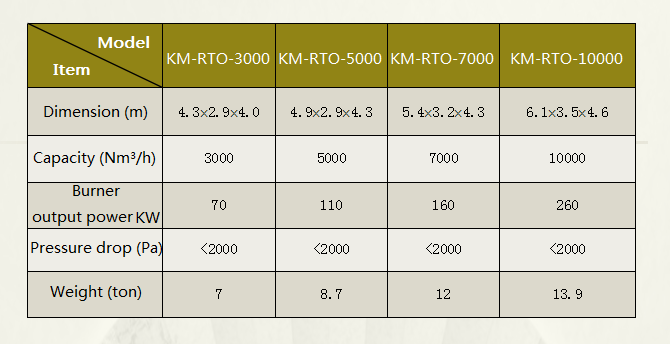

KM-RTO series parameters:

Remarks:

1. The performance parameters of some equipments are listed in the table, which can be designed and manufactured according to the actual working conditions;

2. Ceramic regenerative materials adopt well-known brands at home and abroad;

3. Burners adopt well-known brands.

Device features:

1) Compared with catalytic combustion device, it can deal with organic gas with larger air volume;

2) Heat utilization rate can reach 95%;

3) Gases that cannot be treated by catalytic combustion devices can be treated;

4) The purification efficiency can reach over 98%;

5) No NOx was produced;

6) The switching valve is specially customized, with short action time, small leakage and long service life;

7) Perfect monitoring system design to ensure the safe and stable operation of the system;

8) High degree of automation, simple operation and convenient maintenance.

Application industries:

Organic gas treatment in chemical synthesis process exhaust gas (such as ABS), petroleum refining, PTA tail gas treatment, automobile and machinery manufacturing, painting line and baking room, printed circuit board (PCB), electrical manufacturing, enameled wire, light industry, shoemaking and gluing, printing, metallurgical and iron industry, carbon electrode production and other industries.

Copyright All Rights Reserved @Shanghai Chemmah Industrial Co., Ltd.

Address: No. 528, North Yanggao Road, Pudong District, 200137, Shanghai, China

Email: sales@chemmah.com

WhatsApp & Messenger: +86 158 6847 7948