Prefabricated eco-house, fast assembly

Steel pipes, Laser machinery, UAV

Water/gas treatment, Cooling water

Prefabricated eco-house, fast assembly

Steel pipes, Laser machinery, UAV

Water/gas treatment, Cooling water

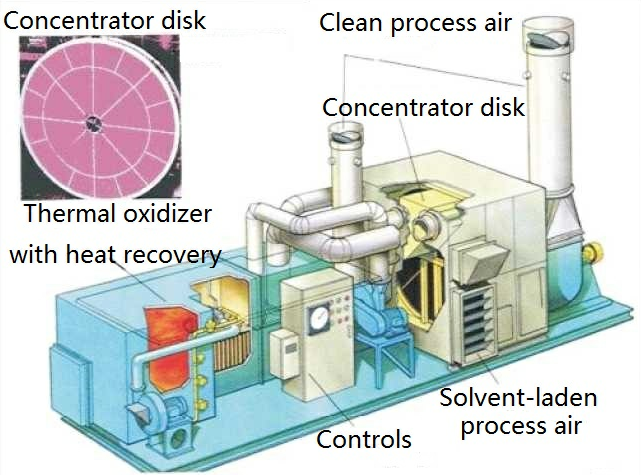

Our zeolite runner concentration system (ROTOR) is superior to the fixed bed system in dealing with waste gas with high air volume and low concentration, continuous operation, efficiency stability and exhaust emission. The runner also has the advantages of low pressure loss, no adsorption loss and few movable components. The hydrophobic zeolite of inorganic honeycomb behind the runner can also be effectively treated for high temperature volatile organic gases.

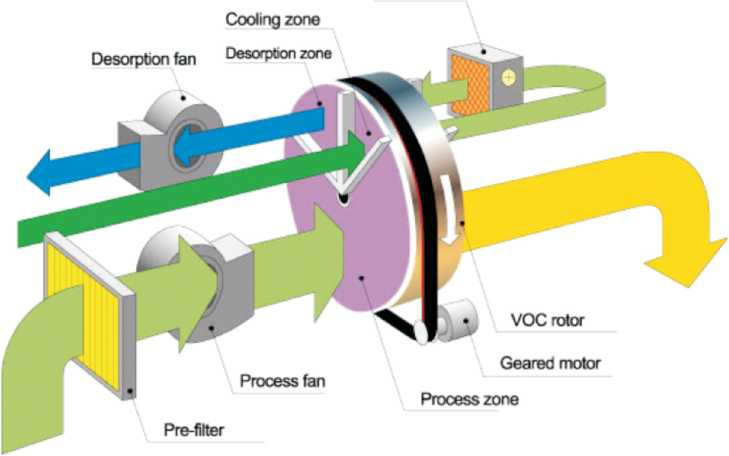

Operating Principle:

VOCs exhaust gas can be effectively adsorbed into zeolite after it is concentrated by hydrophobic zeolite runner to achieve the purpose of removal. Clean gases adsorbed by zeolites are discharged directly into the atmosphere through chimneys. The runner rotates continuously at a speed of 1-6 revolutions per hour, while the adsorbed volatile organic compounds are transferred to the desorption zone. A small heating gas was used to desorb volatile organic compounds in the desorption zone, and the desorbed zeolite wheel rotated to the adsorption zone to continuously adsorb volatile organic gases. The desorbed concentrated organic waste gas is sent to the incinerator for combustion, converted into carbon dioxide and discharged into the atmosphere by steam.

Absorption and concentration:

The VOCs gas with high air volume and concentration below 800 ppm and 40 C is treated and adsorbed by zeolite in the runner to exhaust the clean tail gas into the atmosphere by the system ventilation and frequency conversion fan. The adsorber provides a large amount of gas contact zeolite surface area for the vertical runner (CTR). The runner continues to rotate at a speed of 1-6 rpm. Provide more than 95% VOCs removal rate.

Desorption:

VOCs (volatile organic compounds) in the runner are condensed into saturated zeolite zone, then desorbed by heat flow provided by heat exchanger (about 200 C). After desorption, VOCs are rotated to cooling zone, boasted to be cooled to normal temperature by ambient temperature air, and then rotated to adsorption concentration zone.

Scope of applications:

VOCs emission industries include petrochemical industry, fine chemical industry, spraying, packaging and printing, pharmaceutical and pesticide manufacturing, semiconductor and electronic products manufacturing, wood-based panel and wooden furniture manufacturing, leather, enameled wire, shoemaking, paint, ink, adhesive production, metal casting, etc. The common components of VOCs produced in various industries are hydrocarbons, benzene series, alcohols, ketones, zokors, aldehydes, esters, amines, nitriles (cyanogens), etc.

Copyright All Rights Reserved @Shanghai Chemmah Industrial Co., Ltd.

Address: No. 528, North Yanggao Road, Pudong District, 200137, Shanghai, China

Email: sales@chemmah.com

WhatsApp & Messenger: +86 158 6847 7948