Prefabricated eco-house, fast assembly

Steel pipes, Laser machinery, UAV

Water/gas treatment, Cooling water

Prefabricated eco-house, fast assembly

Steel pipes, Laser machinery, UAV

Water/gas treatment, Cooling water

Low refrigerant content, more environmentally friendly.

The unit will not be damaged, even if operation fails and causes the building of ice at the panels.

Can cool slightly polluted water like water containing oil and blood (particles smaller than 8 mm).

Almost all cooling media can be used with this Falling Film Ice Water Machine.

Open construction for easy cleaning.

| Water chiller | Type | FFM-1200 | FFM-2000 | FFM-2440 | ||

| L*W*H(mm) | 2200*1200*2100 | 2200*2000*2100 | 22200*2440*2100 | |||

| Supply ice water | Supply temperature(℃) | 0.5~2 | ||||

| Tank | Volume(m³) | 1 | 1.8 | 2.3 | ||

| Insulation thickness(mm) | 50 | |||||

| Inlet/outlet diameter(mm) | ¢50 | ¢63 | ¢76 | |||

| Water pump | Pump power(kW) | 1.1 | 1.1 | 2.2 | 3 | 4.5 |

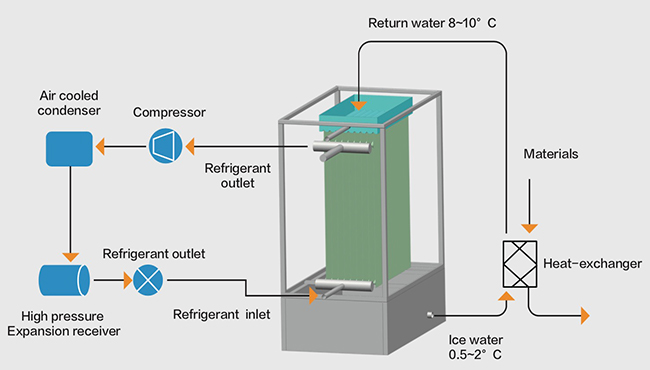

The falling film ice water machine is composed of top water distributor, heat exchange plates, support frame, water tank at bottom and internal circulation water pump. The water tank at the bottom is designed with thermal insulation and a partition board. The water tank is divided into a warm water zone and an ice water zone. If the ice water is used for circulating heat transfer, the water will return to the warm water area after heat exchange.

If the ice water is used for generating process water, the high-temperature water will be directly added into the warm water area, so as to ensure the isolation of the low-temperature ice water and the warm water. Warm water is pumped into the water distributor by the inner circulation water pump, and at a constant flow rate evenly sprayed on the surface of heat exchanger plates, form a thin layer of water falls over the plate. Cooling media goes through inside of the heat exchange plates which heat transfer with water film outside heat exchange plates, instantly cooling the water temperature to below 2 °C, the chilled water directly flowing into the tank of ice water area. Finally the ice water with temperature between 0.5 ~ 2 ℃ is pumped to the working destination for using. Such as storage tank, heat exchanger, the cooling jacket and so on.

Copyright All Rights Reserved @Shanghai Chemmah Industrial Co., Ltd.

Address: No. 528, North Yanggao Road, Pudong District, 200137, Shanghai, China

Email: sales@chemmah.com

WhatsApp & Messenger: +86 158 6847 7948